CRUSHERS AND SHREDDERS

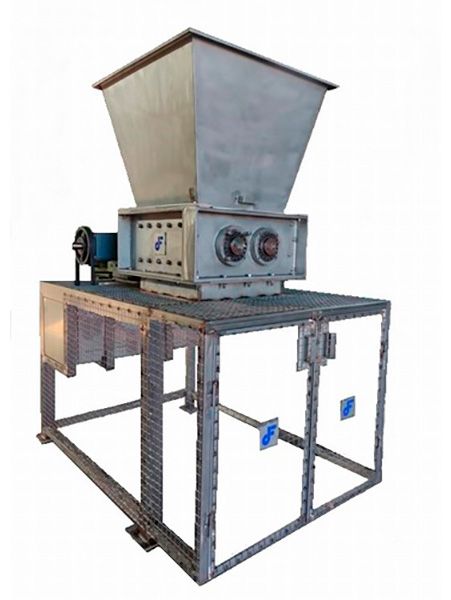

CE marked volume reduction shredders and shredders. Designs in 1, 2 or more rotary drive shafts fully adaptable to customer requirements.

The design of the bone shredder, skin shredder, feather shredder, paper shredder or material of different types and physical properties, developed by Domfesa, is at the forefront in terms of price, durability and production capacity per hour.

Given the configurations studied, calculated and developed by our R&D department, the fragmented or granulated dimensions generated by Domfesa shredders and shredders are fully adjustable as standard.

Depending on the type of application and material to be processed (skins, feathers, bones, paper…), our technical office advises and designs these machines with different power sources, type of transmission and structural construction materials. The shredders are equipped with a gear motor. The power transmission of these can be by belt, which acts as a fuse in any case that may be required, by chain, by mechanical elements or by direct injection.

As for the blades, these machines can be equipped with stainless steel or steels of different alloys. We have different types of treatment, both chemical and mechanical, to exponentially optimise the performance and durability of our blades.

Thanks to the industrialised design of our machines, Domfesa shredders and shredders have a standardised composition that makes maintenance and replacement of parts very simple and adaptable to modular systems on the market.

SHREDDERS

MAYCON Shredder

MEDUM Shredder

PRIME Shredder

Crushers

DESMED Crusher

SHREDDER MAYCON MODEL

- Production between 2 and 4 m 3

- Ideal for small raw materials: meat, bone, fish, minerals, pharmaceutical, plastic recycling, rubber, cork, glass recycling, paper recycling, etc.

- Granulometry according to customer requirements

- With electrical rotary monitoring

- High-quality material for heavy-duty cutting and shredding

- Industrialised design, very easy maintenance

- Sustainable calculation, design and manufacture at every stage.

- Respects the properties of the raw material as much as possible.

SHREDDER MEDUM MODEL

- Working 24 hours a day – Production between 6 and 8 m3

- Ideal for moderate sized raw materials: meat, bone, fish, minerals, pharmaceuticals, plastics recycling, rubber, cork, glass recycling, paper recycling.

- Granulometry according to customer requirements

- With electrical rotary monitoring

- High-quality material for heavy-duty cutting and shredding

- Industrialised design, very easy maintenance

- Sustainable calculation, design and manufacture at every stage.

- Respects the properties of the raw material as much as possible.

SHREDDER PRIME MODEL

- Working 24 hours a day – Production between 10 and 15 m3

- Ideal for large raw materials: meat, bone, fish, minerals, pharmaceutical, plastics recycling, rubber, cork, glass recycling, paper recycling.

- Granulometry according to customer requirements

- With electrical rotary monitoring

- High-quality material for heavy-duty cutting and shredding

- Industrialised design, easy maintenance

- Sustainable calculation, design and manufacture at every stage.

- Respects the properties of the raw material to the maximum.

CRUSHERS DESMED MODEL

- 24 h working – dry materials

- Ideal for: Minerals, pharmaceuticals, plastics recycling, cork, glass recycling, paper recycling, organic fibres.

- Screening

- With electrical rotary monitoring

- Industrialised design, very easy maintenance

- Optimum material quality for shredding and breaking of high-strength solids

- Calculation, design and manufacture with sustainable character in each of its phases.