Slicing and shearing machines: Versatility and quality in farm equipment

Slicers are versatile, high quality tools used in the agricultural industry. Made of carbon steel and stainless steel, they adapt to different types of machinery and offer an environmentally friendly and clean design. With models ranging from basic to special liquid models, they are easy and straightforward to assemble. In this article, we will explore the benefits, technical features, installation processes, maintenance, use cases in different industrial sectors and more about the slit-screwers.

What are the slit-slitters?

Slicers are specialised tools used in different industries, such as agriculture and livestock farming. They are shovel-shaped mechanisms with the function of opening and closing the passage of a product from different conveying systems.

These tools play a crucial role in food and liquid processing, facilitating the proper flow and distribution of food and liquids.

Slotter-screens are mounted at the outlet of hoppers, silos, mechanical conveyors and at the inlets of unloaders.

The shredders are manufactured from carbon steel and stainless steel for strength and durability. Their environmentally friendly and clean design makes them a reliable choice for those looking for sustainable and efficient solutions.

These tools adapt easily to a wide range of machinery, making them versatile and efficient in different working environments. They are easy to install and can be used in conjunction with other Domfesa products or with the company’s own machinery.

The cutter-slitters also offer the possibility of special orders according to the needs and specifications of each customer. This is achieved thanks to a numerical control work system that allows the precise and customised manufacture of these tools.

Benefits of shearers in the agricultural industry

The shredders offer a number of key benefits to the agricultural industry, improving efficiency and optimising production processes. These are some of the benefits that stand out:

-

Greater versatility: Thanks to their adaptable design, the slit-slitters can be adjusted to different machinery and applications, facilitating their integration into existing systems.

-

Optimisation of work: Their easy assembly and compatibility with other Domfesa products or existing machinery allows work processes to be streamlined, saving time and resources.

-

Durability and resistance: Manufactured in carbon steel and stainless steel, the cutter-scrapers guarantee a long service life and resistance to adverse conditions, ensuring optimum performance over time.

-

Numerical control system: Thanks to this system, it is possible to make special orders and adapt the choppers-screwers to the particular needs and specifications of each customer.

-

Replacement and safety service: Domfesa offers an exclusive component replacement service, guaranteeing safety and compliance with customer specifications at all times.

Technical characteristics of the cutter-scrapers

Domfesa’s shredders stand out for their excellent technical characteristics. These agricultural tools are designed with precision and using high quality materials.

- Resistant material: The cutter-scrapers are made of carbon steel and stainless steel, which guarantees their durability and resistance to demanding working conditions.

- Adaptable design: They can be adapted to all types of machinery, making them versatile and compatible with different production systems.

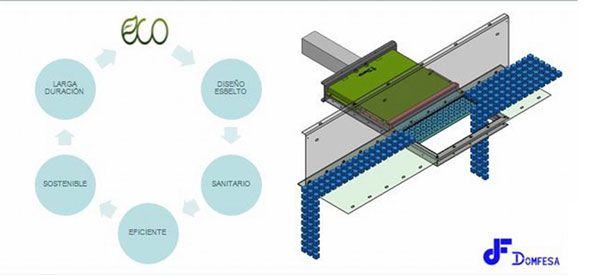

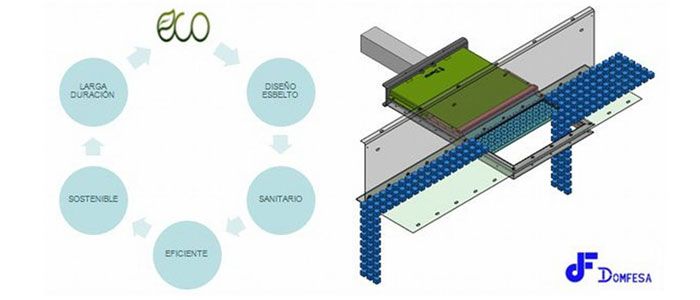

- Variety of models: Domfesa offers different models of chopping and shredding machines, from the ECO series to special models for liquids. This makes it possible to select the most suitable option for the specific needs of each industry.

- Easy installation: They are easy to assemble, as they adapt to Domfesa products using screws or the company’s ecological models. This facilitates their integration into existing production lines.

- Numerical control system: Thanks to this system, it is possible to place special orders according to the customer’s specifications, adapting the cutter-slides to their specific requirements.

Available models of cutter-scrapers

Slicer-scrapers offer a wide range of models adapted to various needs in the agricultural industry. The following are some of the available options:

- ECO Series: With an ecological and clean design, this series stands out for its efficiency and versatility.

- Basic: A simple but effective model, ideal for those looking for a practical and economical option.

- Watertight: Designed to ensure safety and precise control of liquid flow.

- Semi-dose cups: Perfect for accurate and uniform dosing of different products in the industry.

- Dual: Offer greater capacity and flexibility by allowing two products to be dispensed simultaneously.

- Manual: This option allows precise and direct control by the operator, guaranteeing precision in the work.

- Special for liquids: Designed specifically for working with liquids, these choppers-scratchers offer optimum performance in this area.

- Entry-no exit mechanism: This model has a system that regulates the entry and exit of the products, allowing an exhaustive control of the process.

Each model of slice-slitter is carefully designed to meet quality standards and adapt to the specific requirements of different industrial sectors. The choice of the right model will depend on the particular needs of each company and the products they work with. Remember that at Domfesa, we offer an exclusive service for the manufacture and replacement of components for the cutter-scrubbers, ensuring the highest quality and guaranteeing the complete satisfaction of our customers at all times. With our available models, you will find the perfect shredder to optimise your processes and improve your productivity in the agricultural industry.

Installation process of the slit-screens

The assembly of the slitters is a simple and quick process that can be carried out by trained personnel or by the user himself. The steps for a correct installation are detailed below:

- Area Preparation: Before beginning installation, make sure the area is clean and clear. Remove any obstructions or debris that may interfere with assembly.

- Selection of the right model: Determine the model of strainer that suits the needs of the machinery or equipment where it is to be installed. Take into account the type of liquid to be dosed and the technical specifications required.

- Alignment and fixation: Position the sluice-screw on the desired location and check its alignment with respect to the liquid distribution system. Use the screws supplied to securely fasten the chopper-screw to the equipment.

- Piping connection: Connect the necessary piping so that the liquid flows into the chopper-scratcher properly. Make sure that the connections are tight and leak-free.

- Functional test: Once the installation has been completed, it is advisable to carry out a functional test to check that the sluice-screwdrier doses the liquid correctly. Check that there are no obstructions and that the flow is correct.

Con estos pasos, se garantiza una correcta instalación de las tajaderas-raseras, lo que permitirá un óptimo rendimiento y eficiencia en la dosificación de líquidos en diferentes sectores industriales.

Maintenance and replacement of components of the slitters-screens

To ensure the optimal functioning of the slit-screens over time, it is essential to carry out proper maintenance and to be prepared to replace components when necessary.

Firstly, it is important to carry out regular checks of the sliding blocks to identify possible wear or damage. This includes checking the condition of the screws, ensuring that there are no obstructions affecting the flow, and checking the correct adjustment and operation of the liquid inlet and outlet mechanism.

If any worn or damaged component is detected, it is necessary to proceed to the corresponding replacement. Domfesa, as the manufacturer of the slit-screens, offers an exclusive service for the manufacture and replacement of components, ensuring quality and compliance with the customer’s specifications.

To request the replacement of components, it is advisable to contact Domfesa through the available means of contact, such as e-mail or telephone number. In this way, it will be possible to obtain the necessary assistance and purchase the appropriate components to keep the sliding blocks in optimum operating conditions.

Use cases of shear-scrapers in different industrial sectors

Slitting and shearing machines have become indispensable tools in various industrial sectors due to their versatility and efficiency. The following are some outstanding use cases:

- Livestock: In the field of livestock farming, feed chutes are used for the efficient handling and distribution of feed and supplements to livestock. Thanks to their adaptable design, they can be installed in different types of feed mills.

- Agriculture: In the agricultural sector, shredders are used for the precise mixing and application of fertilisers, herbicides and other crop products. Their numerical control system allows precise dosage adjustment.

- Food industry: In food processing plants, the shredders are used in the extraction and transfer of liquids and by-products. Their liquid-tight design ensures hygiene and leak prevention.

- Recycling and waste management: In the field of waste management, shredders are used for the separation and transfer of different materials, facilitating efficient processing and recycling.

These are just a few examples of the sectors where slitting and shearing machines find application. Their versatility and adaptability make them a valuable tool for optimising processes and improving productivity in a wide range of industries.

Frequently asked questions about the slit-scrapers

The following are some frequently asked questions about slit-screens and their answers:

- – What is the difference between a chopper and a squeegee?

- – What materials are used in the manufacture of choppers and scrapers?

- – In which industrial sectors can slitting and scraping machines be used?

- – What is the installation process of slitters-scrapers?

- – How is the maintenance of slitting and shearing machines carried out?

- – How long do the shearing shears last before components need to be replaced?

- – What are the advantages of the slit-screw conveyors in terms of safety and compliance with customer specifications?

These are just some of the most common questions that arise regarding slit-screens. If you have any other questions or concerns, please do not hesitate to contact us or consult our customer service team.

Final considerations on the use of shearers in agriculture and livestock farming

Slicers have become indispensable tools in agriculture and livestock farming thanks to their numerous benefits and versatility. Their ecological and clean design, together with their manufacture in carbon steel and stainless steel, guarantee their durability and resistance in agricultural environments.

These shredders offer a wide range of models adapted to different machinery, making them ideal for use in different industrial sectors such as water management, recycling, waste management and mining. They are easy to install and their numerical control mechanism allows special orders to be made to customer specifications.

Regular maintenance and a reliable component replacement service are important to ensure their smooth operation. Domfesa offers an exclusive service in this area, ensuring safety and compliance with customer specifications.