Belt conveyors are an efficient solution in logistics management and in the production chain. They offer greater precision and efficiency in transport, saving time and costs. In addition, there are different types of conveyor belts, such as chain, belt and roller conveyors. For their correct operation, it is necessary to have different components and accessories such as linear guides, rollers and protection and control systems. The industrial applications of these belts are diverse: they transport heavy loads and small parts, pallets and bulk materials, and are also useful in storage and handling of goods. Companies such as Domfesa offer solutions and products for this industry.

Advantages of conveyor belts

Conveyor belts have become a practical and efficient solution for logistics and production chain management. In this section, the main advantages offered by belt conveyors, their different types and the variety of components and accessories available on the market for their correct operation will be presented.

Time and cost savings in the production chain

One of the main benefits of belt conveyors is the time and cost savings in the production line. Thanks to these belts, heavy loads and small parts can be transported quickly and safely, avoiding manual processes that are slower and can cause wear and tear on staff.

Increased efficiency in logistics management

Another important benefit of belt conveyors is the improvement of efficiency in logistics management. With these belts, transports can be carried out continuously and without interruption, which allows a constant flow of production and reduces downtime.

Reduced errors and more accurate transport

Finally, belt conveyors offer increased conveying accuracy and reduced errors due to their design and operating mechanism. Parts are transported uniformly and without wear problems, bringing higher quality and reliability to industrial processes.

Types of conveyor belts

Conveyor belts are essential for the transport of materials and products in different industrial activities. There are several types of conveyor belts, each with specific characteristics according to the needs of each company and application. The main types of conveyor belts are detailed below:

Belt conveyors

The belt conveyor is the most common conveyor belt in industry and is characterised by a continuous belt with a flat or ribbed surface for transporting materials. The belt is made of different materials such as PVC, rubber, silicone and special fabrics to withstand different loads, temperatures and environmental conditions. These belts are suitable for conveying small to medium-sized objects with a wide variety of shapes, from irregular solids to disc-shaped parts.

Chain conveyor belts

Chain conveyor belts are ideal for transporting heavy loads and large objects. The chain runs the length of the belt and is driven by an electric motor. These belts can also withstand high temperatures and extreme environmental conditions, which makes them suitable for the metallurgical or chemical industry.

Belt conveyors

Belt conveyors are used in the handling of bulk materials such as grain, aggregates or coal. The belt is a continuous belt that rotates on a motorised drum and its surface is embossed to prevent the transported material from moving. They can be made of rubber or PVC and can be adapted to different widths and sizes.

Roller conveyors

Roller conveyor belts are the most economical option for transporting materials in large volumes over long distances. The belt consists of a series of rollers arranged along its length, driven by an electric motor. The transported objects slide over the rollers and are moved by the force of gravity. These belts are suitable for handling heavy loads, although the transport volume is smaller than with other types of conveyor belts.

Components and accessories for conveyor belts

Various components and accessories for conveyor belts are available on the market, allowing customised solutions to be configured and adapted to each type of process. Some of the most common components and accessories are described below:

Modular and PVC belts

Modular and PVC belts are a key component in belt conveyors. The choice of the right belt depends on the type of product to be conveyed and the needs of the process. Modular belts are ideal for conveying products of different shapes and sizes. PVC belts, on the other hand, are suitable for products that require a smooth and even surface for conveying.

Linear and lateral guides

Linear and lateral guides are used to hold the load in position during transport. Linear guides are used in applications where precise transport of the load is required. Lateral guides are used in applications where it is required to block the load laterally and prevent it from falling off the conveyor belt.

Rollers and shafts

Rollers and shafts are the elements that allow the conveyor belt to move. It is important to choose them according to the specifications of the belt and the needs of the process. The rollers can be made of steel or plastic, and their length and diameter vary according to the type of conveyor belt.

Aluminium profiles and stainless steel tubes

Aluminium profiles and stainless steel tubes are used to manufacture robust and resistant structures to support the conveyor belt. These components ensure stability and safety when transporting heavy loads or in environments with extreme conditions.

Protection and control systems

Protection and control systems are essential to ensure the safety of people and the protection of the conveyor belt. Control systems are responsible for detecting problems in the operation of the conveyor belt and alerting the operator to prevent damage to the machinery or the transported load. Protection systems, such as emergency switches or proximity sensors, ensure the integrity and safety of people in the working environment.

Industrial applications of conveyor belts

Transport of heavy loads and small parts

Belt conveyors are ideal for transporting heavy loads and small parts in industry. In this way, materials can be transported quickly and efficiently, without the need for time-consuming manual loading and unloading. Moreover, thanks to their precision and reliability, conveyor belts are a very suitable solution for logistics management and inventory management in the production chain. A wide variety of materials, from small machine parts to large blocks of heavy materials, can be conveyed via the modular and PVC belts. Linear and lateral guides ensure smooth and unobstructed lowering, increasing safety, precision and speed in the conveying process

Transport of pallets and bulk materials

Another common industrial application for conveyor belts is the transport of pallets and bulk materials. In this type of transport, the conveyor belt is responsible for safely and quickly moving pallets of various sizes and bulk materials, such as gravel, sand, or solid chemicals. For this type of transport, conveyor belts with PVC belts are an efficient solution, as they can carry large amounts of weight and offer strength and durability in difficult working conditions. At the same time, to ensure safe transport, side guides and metal profiles can be included to prevent slippage of the conveyed material.

Storage and handling of goods

Belt conveyors are a very useful solution for the storage and handling of goods in industry. For example, they are commonly used in distribution centres and in warehouses for refrigerated or frozen products. In addition, conveyor belts are a very suitable solution for the handling of raw materials and the loading and unloading process of trucks and trains. In this case, chain and belt conveyors can be used, which offer greater strength and durability for the transport of large loads and larger materials. The ease of connection with other equipment, such as roller systems, allows the creation of highly efficient automated storage systems, reducing waiting times and improving inventory management.

Solutions and products for industry

Domfesa

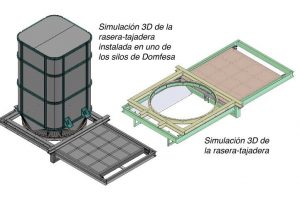

Domfesasl is a company specialised in conveying and material handling solutions with many years of experience in the sector. It is characterised by offering a wide range of high quality products, such as belt conveyors and accessories, and by providing a personalised service to each customer, adapting to their needs and requirements. Among its wide catalogue of products you can find belt conveyors, modular conveyor belts, lateral and linear guides, rollers and shafts, aluminium profiles and steel tubes, and protection and control systems. In addition, they offer maintenance and repair services for their products, ensuring their durability and efficiency.

Success stories and satisfied customers

Transport of materials and products in the industrial sector

In the industrial sector, belt conveyors have proven to be the right solution for the transport of large and heavy materials and products, with the precision and safety required in this type of environment. One of our customers, a leading company in the food industry, has implemented our belt conveyor system for the transport of glass bottles. The result has been greater efficiency in transport and a significant reduction in production time, which has improved the company’s production capacity.

Transport and handling of parts for the automotive industry

In the automotive industry, handling parts with the necessary precision can be a challenge. Our belt conveyors have been implemented by one of the leading automotive parts manufacturing companies. The implementation of our solutions has resulted in reduced part handling times and increased efficiency on the production line, resulting in significant cost savings and improved part handling quality.

Solutions for the logistics and distribution sector

In the logistics and distribution sector, our belt conveyors have been the perfect solution for handling packages and goods. One of our customers in this sector has implemented our belt conveyor system for parcel handling in a logistics centre. The result has been a significant increase in transport efficiency and a reduction in goods handling errors, leading to improved service quality and increased customer satisfaction.

In conclusion

These are just a few examples of the many success stories where our belt conveyors have been successfully implemented in different industrial sectors. Efficiency, accuracy and cost savings have been some of the benefits that our customers have obtained with our solutions. Rely on us to improve the quality and efficiency in the transport of your products.

Quality assurance and customer commitment

Our partner companies are committed to providing high quality products and solutions for their customers, and in the case of belt conveyors, this means a wide range of standard belts and components available for purchase. We offer conveyor belts of different types (belt, chain, belt, roller) and a wide selection of accessories that allow each conveyor to be customised to the customer’s needs.

Wide range of conveyor belts and standard components

- We offer a wide range of belt conveyors, a cost-effective and efficient solution for most industrial applications.

- Our range of standard conveyor belt components includes modular and PVC belts, linear and side guides, rollers and shafts, aluminium profiles and stainless steel tubes, protection and control systems.

- All our material is designed and manufactured to high quality standards, which translates into increased durability, precision and safety on every conveyor.

Download centre and customer service

- We offer a free download centre where our customers can access user manuals, product catalogues and other useful resources for installing, operating and maintaining their belt conveyors.

- Our customer service team is made up of specialised technicians and experts in the transport of goods who are always ready to help customers with any questions, doubts or technical problems that may arise.

- In addition, we offer technical advice and assistance in the planning of goods transport projects.

For more information. Visit the website: