Industrial machinery is nowadays a fundamental element in the productivity of any company, as it speeds up production processes with a lower need for personnel. New technologies and process methodologies have allowed tools to take up less and less physical space and require less and less maintenance.

Within industrial machinery, the airlocks and rotary valves are essential and indispensable in the bulk handling of powders and other solids. Moreover, their mechanics are simple, but their functions have an application in almost all types of industries, especially food and concentrates.

What rotary valves are like

Domfesa is a Spanish company that has specialised over the years in the design and manufacture of various industrial solutions. Through its Innovation, Development and Research department, it manufactures prototypes designed to meet the various manufacturing needs.

Its designs have positioned it as the main support in sectors such as rendering of meat by-products, feed mills and recycling. It also serves companies in the chemical sector, mining, flour mills, agriculture and paper processing, among others. They are one of the main manufacturers of sluices in Spain.

The Domfesa experts explain that the main functions of the rotary valves are the dosing and mixing of all types of materials. The locking function allows the transport of solid elements such as powders, granulates, guts or abrasive elements. In addition, to withstand friction and continuous use, they are generally made of stainless steel, carbon steel or polymers.

Advantages Domfesa has introduced in its rotary valves

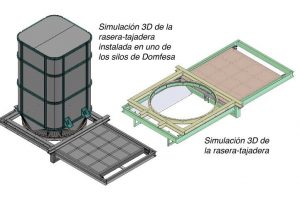

The valves have an inlet, a central part where the rotary system is located and an outlet. Through their R+D+I department, they have incorporated certain advantages to make them more complete.

In addition, carbon steel, stainless steel and polymer alloys make them virtually impervious to wear and tear, making them an excellent investment. They are powerful additions, but take up very little space.

Domfesa offers different models of airlocks ranging from simple but very durable airlocks to automated sluices with automatic cleaning systems and sensors to be able to always be in control of the production process.

In the case of Domfesa, they are produced in different sizes and types to cater for different uses.

According to Domfesa, the priority of the manufacturing companies is to offer products durable and low-maintenance. For this reason, they manufacture with different materials so that buyers have a variety of options. Depending on the type of process and the conditions under which the equipment will work, there will always be a solution that will meet the requirements of their customers.