The scraper is a shovel-shaped mechanism with the function of opening and closing the passage of a product from different transport systems; which is widely used in the food industry. The scrapers are mounted at the outlet of hoppers, silos, mechanical conveyors and at the inlets of unloaders.

They can be manufactured in carbon steel, galvanized steel or stainless steel, and their operation can be by pneumatic cylinder, electric motor or manual control. For any type of improvisation.

In Domfesa we manufacture different models to accommodate and facilitate their assembly by means of screws, adapting them to any machine, making special designs according to the needs and specifications of the client.

MODELS:

Cutter adaptable to conveyor machines or any machine that the customer wants. Designed to handle dry, fine or granulated solid products.

It has a design with fewer features than the ECO Slim, more simplified but at the same time effective. It has a dustproof closure and mobile part acting as a bottom, without leaving the product transported once closed, avoiding contamination of it.

It can be adapted to conveyor machines or any other machine the customer may require.

With a guillotine design, ideal for the prevention of any type of leakage and adaptable to any machine or flange on the market.

With an extra-flat design incorporating welded to any channel for a totally watertight function thanks to its external cable gland, adaptable to the machine desired by the customer, including adaptation frames.

With an elongated design and an impression of multiple “symmetrical hoppers” in its interior getting a dosage of the material.

Two fused squeegees that allow for individual or simultaneous material dosing.

Simple design with a manual shovel with a funnel-shaped material inlet that can be replaced by frames with the dimensions specified by the customer.

-

-

-

-

-

-

-

-

- Liquid specials:

-

-

-

-

-

-

-

Distributed in simple designs with manual shovel for a watertight function, thought for the irrigation or for many more uses where the watertightness is required, according to the needs of the client.

Designed to allow material or any other product to enter by gravity, preventing it from leaving once it has entered thanks to its anti-return system, with personalized designs and giving the possibility of being used as a unit counter.

-

-

-

-

-

-

-

-

-

- Specials of large dimensions:

-

-

-

-

-

-

-

-

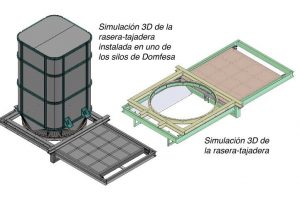

Designed to be installed under a silo to control its discharge, with custom designs for extra large sizes.

At Domfesa we are pioneers in the design and manufacture of extra large squeegee blades, with a special design to avoid clogging and a great reduction of liquid losses with guaranteed semi-sealing thanks to its operation specially designed and developed by our R+D team. It can be manufactured in any diameter requested by the customer and with the technical specifications required.

Domfesa has a wide stock of mounted scrapers and spare parts of the same ensuring the customer a quick replacement of components in case of failure.